| CRONUS (HEU-UKRI) |

| BLOW HEU (UKRI) |

Information to be available shortly (Environment & Water)

| DIGINTRACE HEU (EU-UKRI) |

Information to be available shortly (Manufacturing & Supply Chain)

Information to be available shortly (Manufacturing)

| BIORECER (EU-UKRI) |

(Manufacturing & Supply Chain)

https://biorecer.eu/

| VALZEO (EU-UKRI) |

| Triple Carbon Reduction (OFWAT) |

| CCEU (OFWAT) |

| CARDIMED (HEU-UKRI) |

| NOVAFUEL (HEU UKRI) |

https://www.bl2f.eu/about-the-project/

01/05/2019

Commenced

Deep Purple (EU Funded H2020: H2020-BBI-JTI-2018-837998)

CONVERSION OF DILUTED MIXED URBAN BIO-WASTES INTO SUSTAINABLE MATERIALS AND PRODUCTS IN FLEXIBLE PURPLE PHOTOBIOREFINERIES

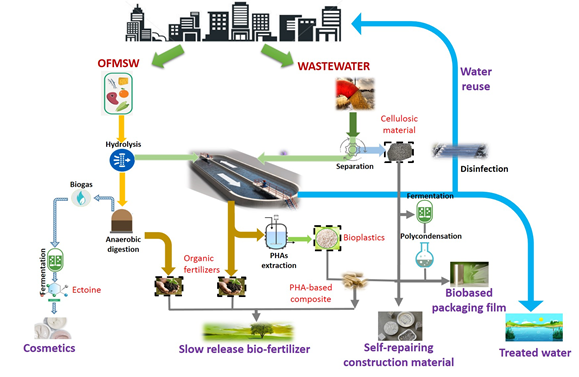

DEEP PURPLE creates a holistic consortium to transform diluted urban bio-wastes,

including mixed waste streams, organic fraction of municipal solid waste (OFMSW), wastewater (WW)

and sewage sludge (SS), into feedstock for bio-industry to obtain sustainable bio-products.

This revolutionary concept will be implemented in a novel Single-Site Multi-Platform Concept

(Biomass, Cellulose and Biogas) to replace current polluting destructive practices with new value added concepts.

The beneficial use of bio-waste is obtained by an innovative combination of optimized recovery technologies

and novel solutions: the Purple Phototrophic Bacteria (PPB) PhotoBiorefinery. The use of PPB -the most versatile

metabolism reported- ensures the adaption to fluctuating and diluted waste streams to support a stable profitable production chain. The first PPB PhotoBiorefinery in the EU (the biggest worldwide) will be validated

in different environmental, economic, logistic, and social scenarios.

The concept will be implemented by end-users from four municipalities, namely Madrid (ES), Toledo (ES),

Třinec (CZ) and Velká Polom (CZ) to transform bio-wastes (OFMSW: 422 t/y, mixed waste: 438,000 m3/y)

into high-added value bioproducts: fine chemicals (bio-cosmetics), fertilizers, bio-packaging and self-repairing

construction materials. The market uptake of DEEP PURPLE is facilitated by optimal logistics of

bio-wastes conversion (reduction of landfilled OFMSW: 60%, WWTP solids recovery: 71%), and bio-products

quality to favor their commercialization (440 t/y). The integration of value chains is boosted by relevant

stakeholders participation and innovative business models, minimizing waste and maximizing benefits

(85 M€ benefits, GHG emissions savings: 11,300 tCO2eq/y in 2025). Key communities (social engagement strategies)

will participate in the new value creation, calibrating the returns of the project like social

innovation promotion and creation of new opportunities along the urban value cycle.

DAS Funded under FASS programme, of full implmentation of the project in phase 2 to research, develop and validate an advanced Machine Learning and AI solution for screening Electrical and Electronic Devices in Luggage.

The High-Speed Scanning for detecting Tampered Electrical Electronic Devices (HISTEED)

Government Funding Council (DSA): ACC106975

The aim of this project is to explore the feasibility of a novel Image Processing and Event-Based Machine Learning technology that increases the accuracy, speed as well as the systematic scale up of screening Electronic and Electrical Devices for hand luggage.

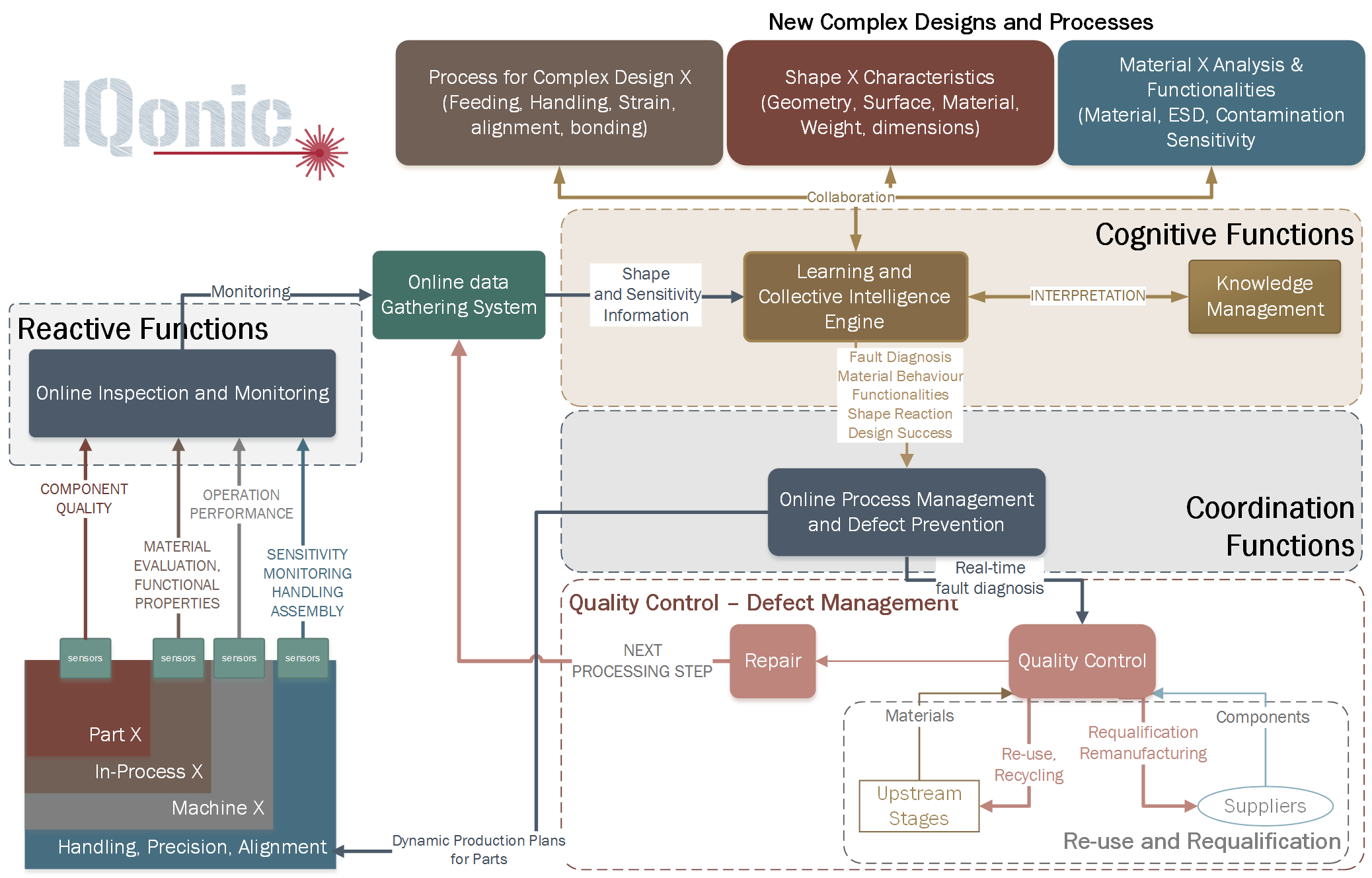

Innovative strategies, sensing and process Chains for increased Quality, re-configurability, and recyclability of Manufacturing Optolectronics

H2020-NMBP-FoF: 820677

Advances in optoelectronics technologies is causing a revolution in consumer electronic goods, solar energy, communications, LED, industrial laser, and other fields. At present, the optoelectrical manufacturing is facing significant challenges in dealing with the evolution of the equipment, instrumentation and manufacturing processes they support. The industry is striving for higher customisation and individualisation, implying that systems configurations need to change more frequently and dynamically. IQONIC will offer a scalable zero defect manufacturing platform covering the overall process chain of optoelectrical parts. IQONIC covers the design of new optoelectrical components and their optimised process chain, their assembly process, as well as their disassembly and reintroduction into the value chain. IQONIC will therefore comprise new hardware and software components interfaced with the current facilities through internet of things and datamanagement platforms, while being orchestrated through eight (8) scalable strategies at component, work-station and shopfloor level. The IQONIC technologies will be demonstrated in 4 demo sites covering a wide range of products and processes. The impact of IQONIC to the European optoelectronics manufacturing industry, but also the society itself, can be summarised in the following (with a horizon of 4 years after project ends): (i) increase of the in-service efficiency by 22%, (ii) increased flexibility with 16% faster reconfiguration times, (iii) 10% reduction in production costs through recycled components and materials, (iv) improved designs for assembly and disassembly and, (v) about 400 new jobs created and (vi) over 39 MEUR ROI for the consortium. To do that we have brought together a total of seventeen (17) EU-based partners, representing both industry and academia, having ample experience in cutting-edge technologies and active presence in the EU photonics and manufacturing.

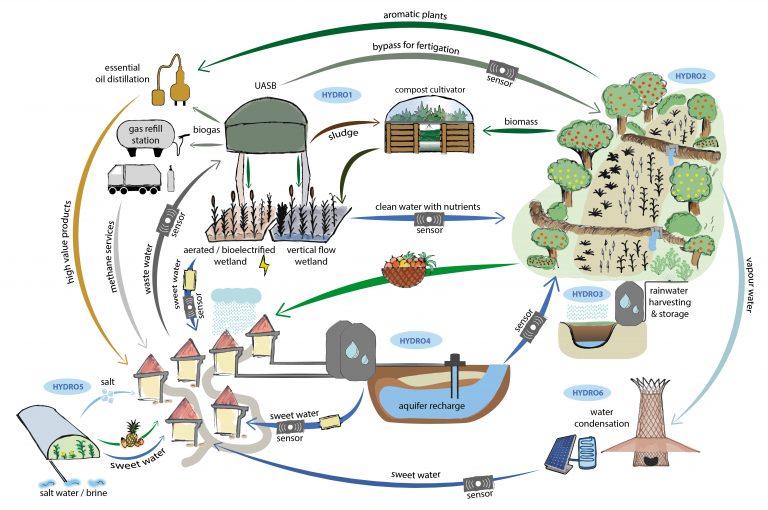

Demonstration of water loops with innovative regenerative business models for the Mediterranean region (HYDROUSA)

H2020-EU (3.5.2.2-4): 776643

HYDROUSA will provide innovative, regenerative and circular solutions for (1) nature-based water management of Mediterranean coastal areas, closing water loops; (2) nutrient management, boosting the agricultural and energy profile; and (3) local economies, based on circular value chains. The services provided lead to a win-win-win situation for the economy, environment and community within the water-energy-food-employment nexus.

HYDROUSA water loops will include water from non-conventional sources including wastewater, rainwater, seawater, groundwater and vapour water, all resulting in recovered and marketable products. HYDROUSA will demonstrate at large scale the feasibility and sustainability of innovative, low-cost water treatment technologies to recover freshwater, nutrients and energy from wastewater, salt and freshwater from seawater, and freshwater from atmospheric water vapour. Water conservation solutions including aquifer storage and sustainable agricultural practices including fertigation will be applied. The solutions will be demonstrated on 3 major touristic islands in Greece. Detailed technical and financial deployment plans will be established for replication in additional 25 locations worldwide. Through the on-site water loops of HYDROUSA, complex supply chains for resource recovery are not required, as producers are directly involved as consumers of derived products. HYDROUSA will combine traditional skilled workmanship with modern ICT integration in beautiful and smart automation systems. HYDROUSA will revolutionise water value chains in Mediterranean areas and beyond, from water abstraction to sewage treatment and reuse. The proposed HYDROUSA solutions show massive potential to change the way humans interact with water, food and energy.

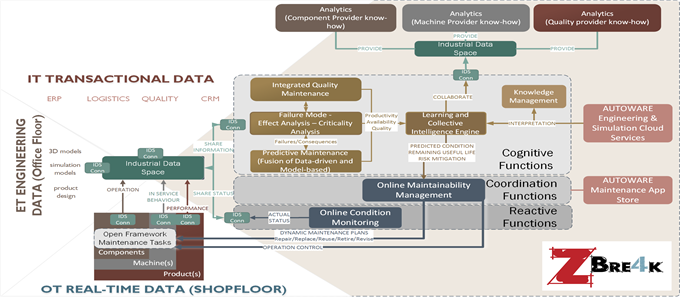

Strategies and Predictive Maintenance models wrapped around physical systems for Zero-unexpeted-Breakdowns and increased operating life of Factories

(Z-BRE4K)

H2020-FOF-768869

Funding scheme: IA

Project acronym: ZBRE4K

Duration (months): 48

Newly built machines start their service life cycle with standard and well specified performance signatures. Components of these machines function and work as expected and a well-defined modular maintenance (preventive maintenance) for a while would fulfil the uptime/downtime plans and schedules of the companies that utilise them. The problem arises when machines and building components, or the collective performance of the components manifesting themselves as the overall performance diminish due to depreciation. Such gradual depreciation normally leads to unexpected failures of the machine or its individual building blocks. In addition to failures, such out of norm machines produce faulty or dangerously border-line products; both causing significant costs, energy waste, as well as productivity and other efficiency shortcomings in manufacturing processes. Capitalising on the findings of the Industry 4.0 evolution, Z-Bre4k will leverage the reference architecture and operating system of the FoF11/AUTOWARE , in order to develop a highly adaptive real-time Machine (network of components) Simulation platform that wraps around the physical equipment for the purpose of predicting uptimes and breakdowns – thus creating intuitive maintenance control and management systems. This will be coupled with novel strategies and a CPPS based operating system, which when deployed in the field, are expected to increase maintainability and operating life span of production systems. The foundations will be based on the convergence of Engineering Technology (ET), Operational Technology (OT) and IT towards consolidating actionable intelligence from manufacturing assets performance modelling, for leveraging predictive maintenance for increased operating life of CPPS.

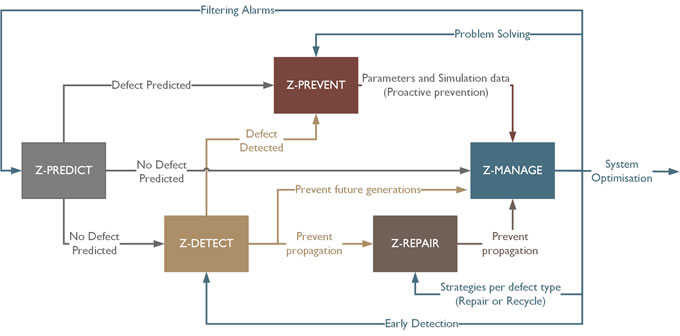

Zero-defect manufacturing strategies towards on-line production management for European factories

H2020-FOF-723906

Funding scheme: IA

Project acronym: Z-Fact0r

Duration (months): 42

Partners: Greece (CERTH and Atlantis Engineering), Cyprus (CETRI), UK (Brunel University and Microsemi), Switzerland (EPEL), Italy (Holonix, Interseals, Confindustria, and SIR), Spain (Datapixel), and Portugal (Inova, and Durit Metal Duro).

In this project event-based adaptive control and optimisation solution to minimise defect in the discrete automated manufacturing process. The machines and the robots will adapt to the variations in material, customer requirements and overall environmental conditions with the purpose to reduce production defect to a minimum and eventually to zero.

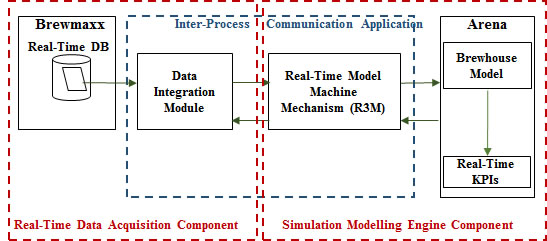

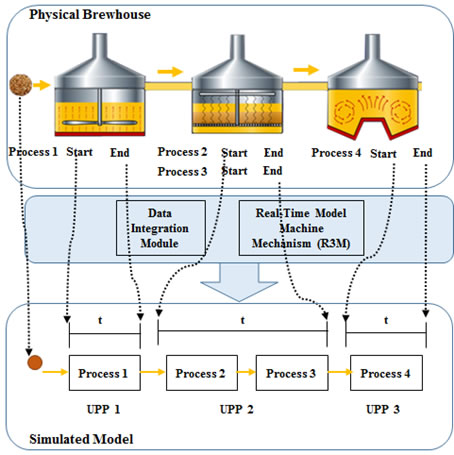

Automatic Real-Time Translation of Plant Data into Management Performance Metrics: A Case for Real-Time and Predictive Production Control - Brewery Technology

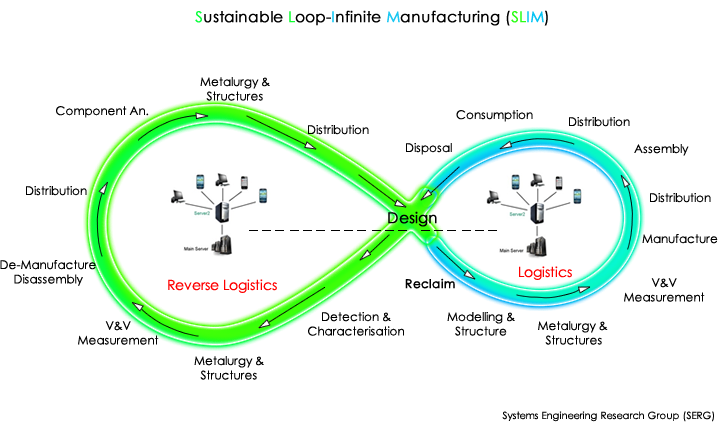

The Sustainable Loop-Infinite Manufacturing Initiative.

- Design philosophy for sustainable, traceable, reconfigurable, and re-manufactureble products

- Machine tools and techniques for automated detection, tracking and tracing, automatic disassembly, and production processes that are capable of exchanging the necessary data and knowledge vertically and horizontally throughout the supply chain (considering the full life cycle, in our case indefinite life cycle of products and service).

- Use of advance materials technologies for design and development of highly recyclable and reconfigurable components and devices – to retain the energy and materials within the lifecycle of products, composites and material. No Loss Philosophy.

- Create a robust and encompassing information architecture to ensure maximum traceability, security, mobility that facilitates implementation of complex optimisation techniques to maximise efficiency and minimise waste.

- A virtual interactive environment in which customers, industrialists, researchers, and education sector can follow this infinite loop. To discuss, understand, influence and adopt.

Further information and expression of interest click here.

EventTracker can be considered as a smart recorder of events.

Analogous to a Blackbox but not only a recorder but an instrument that facilitates preliminary data and knowledge construction . [Better Situation Awreness]

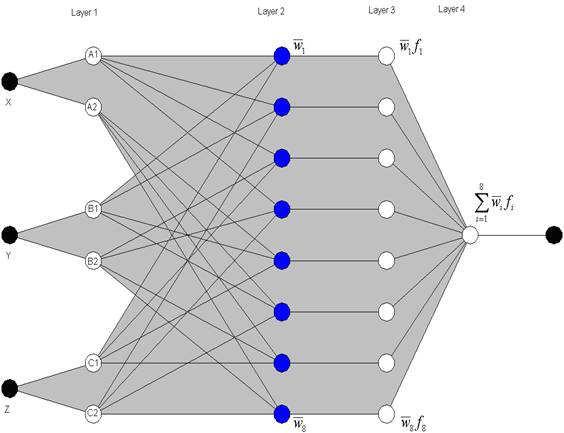

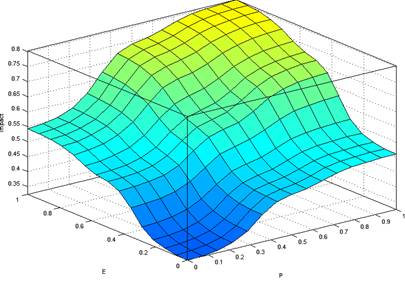

Applications: Real-Time Input Variable Selection and Sensitivity Analysis.

Motivation

Link to Presentation and relevant publications

![]()

Foundation

NEAR-REAL VIRTUAL ENVIRONMENT (NERVE) FOR PHANTOM LIMB PAIN: System Integration, Optimisation and Personalisation

- Motion Detection and Virtual Limb Re-Embodiment Adaptation: Personalisation and Adaptation of Movement, Visual and Propiceptive Feedback. (proof of concept) - [Achieved]

Demo (by Antoine Mallet)

Satistica Quality and Utility Inspection Device (SQUID)

Human-Based Network Capability Models:

Aim: To build a fundamental conceptual model which can predict a group of individuals’ collective (Network) capability.

Objectives:

- Use an existing model of “Individual’s Capability” and extend the concept to human networks

- Determine the factors in human networks (natural or by design) that may affect collective capability – Network Dynamics

- Construct an analytical-conceptual model that describes collective capability

- Test the model through empirical studies

Beneficiaries:

- Such model can enable team builders and group leaders assess and compare the capability of human based networks and thus predict performance.

in other words

- The model enables decision makers with an objective instrument to assess current capabilities and conduct what if scenarios.

more importantly;

- The proposed empirical model will also allow team builders to assess the effect their intervention on team capability may have.

SinglX: Next Generation for Production Process Monitoring and Optimisation

Sponsored by Acontrol and in collaboration with University of Coimbra

The Theory and Modelling of Individual's Capability - Impact and Utilisation of Resources

SinglX: Full R&D - Sponsored by EPSRC

Like in many other manufacturing control solution providers, existing solution for real-time decision support enjoys statistical analysis of input data collected from a series of data entry points throughout the plant, leading to a summary of parametric performance indicators. It seems that current shop floor performance analysis tools available in the market lack the capabilities to reduce decision making process overheads. Since they are either indicators of real time performance of the system or a simulated result of past observations. There is a need for an automatic data interpretation capability which could take pressure off managers to confidently re-schedule the production plan to improve performance and reduce cost.

One of the outcomes of this project has been a novel real-time sensitivity analysis called EventTracker (for details please view list of publications).