LeakFree: Development of quality control system for leak-free fuel tanks

Background

Nowadays, the usage of plastic fuel tanks dominates in the automotive industry over steel tanks as they offer numerous advantages such as lower weight, higher corrosion resistance, better crash performance and lower total system costs. Tank manufacturing from plastics and composites has been adapted to mass production to meet the ever growing demand. The management of quality control systems for the factory environment poses challenges in the absence of relevant experience in the development and use of in-situ non-destructive evaluation technologies. The problem currently faced by the automotive industry is that most techniques that meet accepted leak detection sensitivity requirements are manually intensive and operator dependent. Mechanised leak detection techniques with higher sensitivity do exist; however they are characterised by high investment and operational costs. Hence, their implementation is not economically feasible as the related costs outweigh their benefits for automotive QC purposes.

Objectives

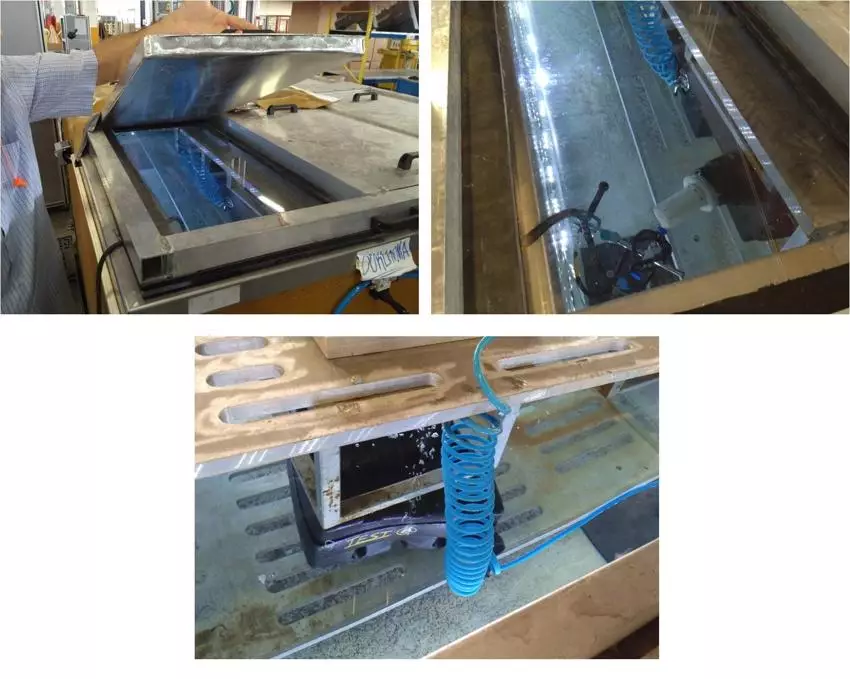

The LeakFree project is targeted at bringing to market a low cost leak detection system that is fast, accurate, traceable and automated for the mass production environment of the fuel tank production industry. The project should set itself up around the fuel tank test bath where the fuel tank is submerged into the water and listened to by the LeakFree system.

Benefits

The system eliminates the disadvantages associated with the manual-intensive and operator dependent techniques currently employed by the industry, through the use of acoustic emission.

Project Partners

- Floteks

- iKnowHow

- Brunel University London

For more information, please visit the LeakFree website

Meet the Principal Investigator(s) for the project

Professor Tat-Hean Gan - Professional Qualifications CEng. IntPE (UK), Eur Ing BEng (Hons) Electrical and Electronics Engg (Uni of Nottingham) MSc in Advanced Mechanical Engineering (University of Warwick) MBA in International Business (University of Birmingham) PhD in Engineering (University of Warwick) Languages English, Malaysian, Mandarin, Cantonese Professional Bodies Fellow of the British Institute of NDT Fellow of the Institute of Engineering and Technology Tat-Hean Gan has 10 years of experience in Non-Destructive Testing (NDT), Structural Health Monitoring (SHM) and Condition Monitoring of rotating machineries in various industries namely nuclear, renewable energy (eg Wind, Wave ad Tidal), Oil and Gas, Petrochemical, Construction and Infrastructure, Aerospace and Automotive. He is the Director of BIC, leading activities varying from Research and development to commercialisation in the areas of novel technique development, sensor applications, signal and image processing, numerical modelling and electronics hardware. His experience is also in Collaborative funding (EC FP7 and UK TSB), project management and technology commercialisation.

Related Research Group(s)

Brunel Innovation Centre - A world-class research and technology centre that sits between the knowledge base and industry.

Partnering with confidence

Organisations interested in our research can partner with us with confidence backed by an external and independent benchmark: The Knowledge Exchange Framework. Read more.

Project last modified 16/03/2021