DiMOS: Digital monitoring of ships

Ships are a high-value asset and often operate in a hostile environment. To ensure their integrity, a smart intelligent asset integrity and maintenance platform is needed for managing the uncertainties and the risks for the people, the environment and the very expensive assets throughout their service life.

The Digital Monitoring of Ships (DiMOS) project aims to develop a disruptive integrated software platform capable of performing prescriptive maintenance of ship's structure, machinery and auxiliary system. It will do that by utilising data from wireless condition monitoring and diagnostic systems, implementing big data analytics, and integrating maintenance actions/prescription database powered by advanced deep learning algorithms. It will also select the best maintenance strategy (as prescription) for the targeted ship asset, based on the faults or conditions observed. Incorporating such intelligent software in maintenance will enable diagnostics and proactive maintenance, reducing assets downtime, and enabling a greater level of control and efficiency.

Objectives

The key objectives of the DiMOS project are:

- Optimisation of sensor system for real-time condition monitoring of machinery and structure (hull) of ships;

- Development of intelligent diagnostic and prognostic models to detect faults or failures in ship;

- Development of risk assessment and failure analysis models;

- Development of maintenance procedures database;

- Design and development of machine learning based advanced data analytics and processing models for prescriptive maintenance;

- Integrated intelligent software platform for real-time condition monitoring and prescriptive maintenance of ships structure and machinery.

Benefits

- Reduced reliance on experienced and expert inspection engineers to process condition monitoring data and devise a maintenance plan;

- Reduced interpretation time in devising and implementing maintenance actions reducing maintenance hours by 70%;

- Automatisation of safety or maintenance operations to the extent where maintenance operations do not require human intervention;

- Reduction of assets unscheduled downtime by 25%, cost by 35% and will improve performance and efficiency of asset;

- Operators will perform cost-effective maintenance based on the risk profile of faults detected.

Brunel Innovation Centre's role

Brunel Innovation Centre of Brunel University will bring to the DiMOS project its knowledge in both condition and structural health monitoring. It will process the big data generated by monitoring sensors by combining signal processing algorithms and machine learning models for real-time condition monitoring and health assessment of key subsystems and components of ships.

Summary

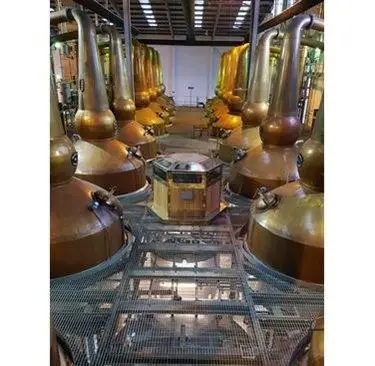

The project met with some delays at the data collection stage due to the COVID-19 pandemic limiting access to ships but fortunately with assistance from Grant’s Distillery (pictured) in Scotland relevant data could still be acquired.

The DiMOS Project progress has created a system that can eliminate unnecessary tasks so that resources can be focused on those that improve the through-life cost of asset ownership and add value.

With a capability to provide an automated early warning system for impending machinery failure, the system is now ready to be rolled out to industries outside of marine too. Potential applications for the system include power generation, automotive and aerospace.

The system is currently installed at a shipping company and more businesses are being approached to further develop the system and ensure its rigidity in the first quarter of 2021.

Copper stills at Grant's Distillery

Copper stills at Grant's Distillery

Project Partners

You can find out more about this project at www.dimosproject.com.

Meet the Principal Investigator(s) for the project

Professor Tat-Hean Gan - Professional Qualifications CEng. IntPE (UK), Eur Ing BEng (Hons) Electrical and Electronics Engg (Uni of Nottingham) MSc in Advanced Mechanical Engineering (University of Warwick) MBA in International Business (University of Birmingham) PhD in Engineering (University of Warwick) Languages English, Malaysian, Mandarin, Cantonese Professional Bodies Fellow of the British Institute of NDT Fellow of the Institute of Engineering and Technology Tat-Hean Gan has 10 years of experience in Non-Destructive Testing (NDT), Structural Health Monitoring (SHM) and Condition Monitoring of rotating machineries in various industries namely nuclear, renewable energy (eg Wind, Wave ad Tidal), Oil and Gas, Petrochemical, Construction and Infrastructure, Aerospace and Automotive. He is the Director of BIC, leading activities varying from Research and development to commercialisation in the areas of novel technique development, sensor applications, signal and image processing, numerical modelling and electronics hardware. His experience is also in Collaborative funding (EC FP7 and UK TSB), project management and technology commercialisation.

Related Research Group(s)

Brunel Innovation Centre - A world-class research and technology centre that sits between the knowledge base and industry.

Partnering with confidence

Organisations interested in our research can partner with us with confidence backed by an external and independent benchmark: The Knowledge Exchange Framework. Read more.

Project last modified 23/02/2021