Dr Roohollah Babaei-Mahani

Honorary Reader

- Chemical Engineering

- College of Engineering, Design and Physical Sciences

Research Interests

- Energy Storage

- Risk & Safety of Hydrogen Transport and Storage

- Microwave Technology

- Corrosion

- Computational Fluid Dynamics (CFD)

- Phase Change Material

Research grants and projects

Project details

- Treatment of Drill Cuttings using an Advanced Thermal Processor

Drilling operations, both offshore and onshore, generate millions of tons of drilling waste annually. This waste cannot be discharged directly into the environment without treatment and requires proper management. The composition of drilling waste is influenced by the chemical additives and organic materials present in the drilling fluid, as well as the mineralogy of the rok formation.

Untreated drill cuttings pose risks to public health and can lead to significant environmental impacts. Consequently, environmental agencies strictly regulate the disposal of drill cuttings in both onshore and offshore operations. Most countries prohibit the discharge of drilling waste containing more than 1% oil by weight.

This research investigates the use of an Advanced Thermal Processor (ATP) for the treatment of drill cuttings. The study focuses on the removal of oil contamination and coompares the results for water-based and oil-based drilling waste samples collected in Qatar and Oman.

- Corrosion in Ageing Jack-Up Drilling Rigs

Corrosion represents a significant financial burden to the oil and gas industry, amounting to billions of pounds annually. This study examines the impact of cold-stacking on jack-up drilling rigs, highlighting how prolonged idling accelerates structural deterioration through corrossion. Furthermore, it outlines effective strategies for mitigating and managing the associated risks to ensure asset integrity and operational safety.

Completed (link below for the paper):

mdpi/2077-1312/13/3/495

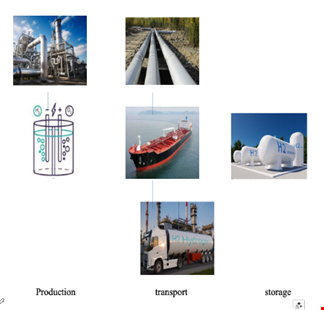

- Risk Analysis and Management of Hydrogen Handling Facilities

Hydrogen is expected to play a crucial role as a future energy source. However, its production, transport and storage involve inherent risks. To effectively manage these risks, it is essential to establish approperiate prevention and protection measures.

Since hydrogen handling constitutes a complex socio-technical system, traditional risk assessment methods are often inadequate, as they fail to capture the interconnected nature of risks within such systems.

This research aims to develop a comprehensive methodology for an integrated framework that combines artificial intelligence and system dynamics to support risk assessment and management in the hydrogen handling facilities.