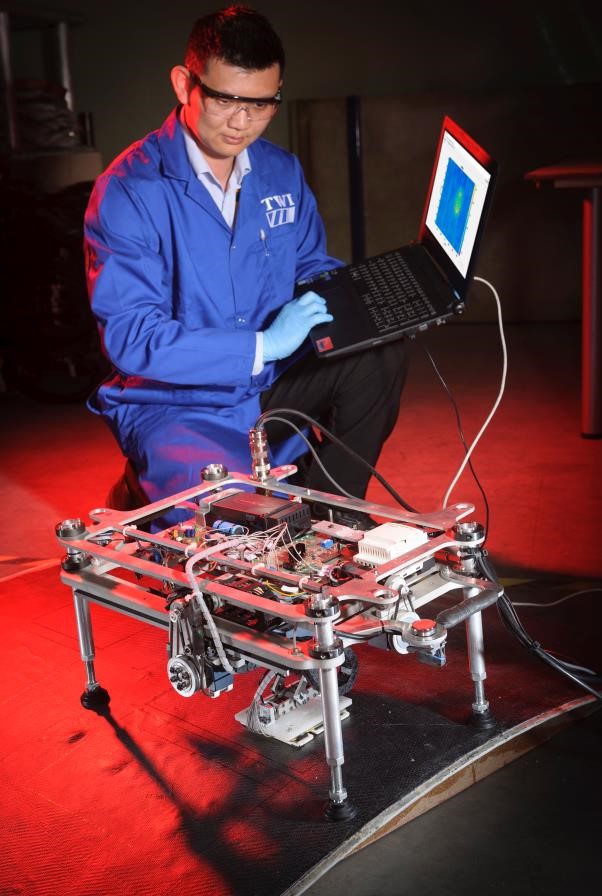

Smart Non-Destructive Testing

The Smart Non-Destructive Testing (NDT) team encompasses the synergistic combination of artificial intelligence (AI) with NDT systems tailored to inspecting of components at different stages for the whole application life cycle. The AI includes the research and development of automated defect recognition/characterization, dexterous automated 3D positioning/localisation, fusion approaches, machine learning and other rapidly exploitable technologies (i.e. drone) as supplement of the NDT solution aiding the user in decision making and reduce subjective errors. The target industry sectors include Transport (Aerospace, Marine, rail), nuclear, energy (electric, wind, solar, hydro), renewables, civil, healthcare, electronic (MEMS or NEMS) and bio-manufacturing.

The core research areas the team focus are:

- Defect/abnormalities identification and quantification such as location, shape and size measurements

- Complete field scanning methods

- Automated detection and/or classifications algorithm including machine learning for increasing productivity and reducing human error

- In-situ NDT inspection methods (i.e. UT, PUAT, Ultrasonic guided wave, laser, optical, x-ray, CT)

- Purpose built NDT system appropriate for inspecting complex geometric component

- High accuracy non-contact scanning (i.e. laser)

- Data fusion for intelligent automated part sentencing

- Analytical and computational models to predict bespoke NDT sensor performance

- Test rig realisation for benchmarking and validation

- Allied technology development such as drone and underwater ROV

- Wireless communication

- Energy harvesting

Back to homepage