Additive manufacturing (AM) of construction materials has been one of the emerging advanced technologies that aim to minimise the supply chain in the construction industry through autonomous production of building components directly from digital models without human intervention and complicated formworks. However, technical challenges need to be addressed for the industrial implementation of AM, e.g. materials formulation standardization, and interfacial bonding quality between the deposited layers amongst others.

This project will work on addressing the aforementioned challenges. Ongoing research actions are currently aimed towards partly replacing ordinary Portland cement (OPC) with industrial by-products. However, the AMTC project targets the development of eco-friendly cementitious mix formulations reinforced with commercially available additives and agricultural waste to achieve structural load-bearing building blocks produced by AM technology.

There are crucial links between the material design formulations and the printing system for the manufacturing of complex 3D geometries. AM uses a combination of materials science, architecture and design, computation, and robotics.

This project considers the market uptake perspectives, human safety, and the risk of environmental contamination, in light of events such as pandemic and natural disasters rapid shelter or quarantine provision without the intervention of humans, done by robots/3D printers on sites has huge potential.

Publications

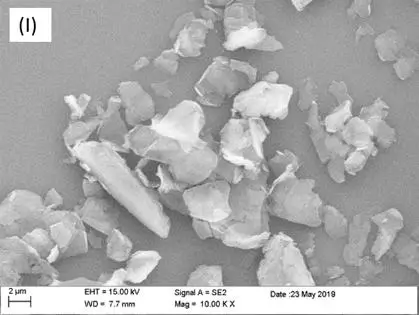

Graphene-based additive material

Graphene-based additive material

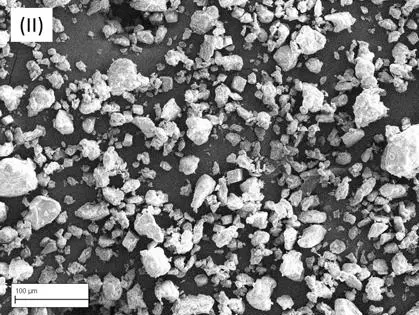

Nano-clay additive material

Nano-clay additive material

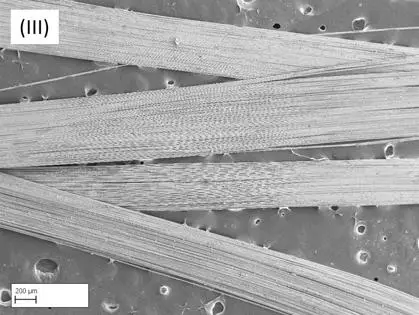

Fibre additive material

Fibre additive material

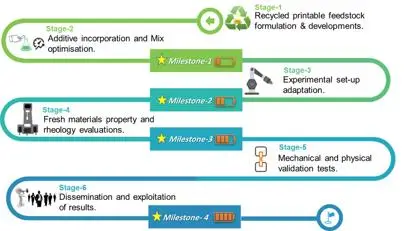

Stages of AMTC project activities and project milestones

Stages of AMTC project activities and project milestones

3D printing of cementitious composite

3D printing of cementitious composite

Meet the Principal Investigator(s) for the project

Related Research Group(s)

Resilient Structures and Construction Materials - RIMS research group brings together material scientists and structural engineers to deliver resilient infrastructure (buildings, bridges etc.) made of sustainable, advanced materials to perform under harsh natural environment and human-induced hazards.

Partnering with confidence

Organisations interested in our research can partner with us with confidence backed by an external and independent benchmark: The Knowledge Exchange Framework. Read more.

Project last modified 19/10/2021