SonicSMR: AI and ultrasonic enhanced additive manufacturing for modular reactors

Background

Metal additive manufacturing has gained higher interest from the nuclear sector to manufacture complex components compared to subtractive manufacturing in order to reduce the scrap rate and reduce manufacturing lead times. However, it is not fully adopted and utilised in the supply chain due to high risks of defects such as interlayer adhesion (lack of fusion) and micro/macroscale porosities, which leads to reduce the quality of components. In order to maintain high-quality products in the production line, it is also needed to monitor and identify defects as early as possible to achieve effective countermeasures.

Objectives

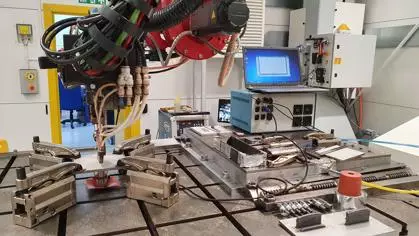

SonicSMR project is funded by The Department for Business, Energy & Industrial Strategy (BEIS) Energy Innovation Programme , within The advanced manufacturing and materials competition (AMM). It aims to address these challenges using a multidisciplinary approach, coupling laser-based metal AM process with power ultrasonics, in-process optical process monitoring, process design optimisation techniques and AI-based automated defects recognition and decision support tool to achieve zero-distortion, zero-defects components manufacturing. Specifically, the project will allow to develop further expertise in AM equipment focused specifically on the manufacture of SMR metallic components.

The SonicSMR solution will offer an innovative solution and system for AM manufacturing in terms of overall productivity, quality and competitiveness through the integration of the ultrasonic system, online optical inspection systems, data interpretation AI algorithms and software, and enhanced process optimisation technique and decision support tool to produce right-first-time metal AM parts with zero distortion and >96% yield. The SonicSMR system will enable AM technology to realise its full economic potential and unlock the full design freedoms offered by AM. By addressing fundamental technical challenges in the nuclear parts and components AM application, the innovation implemented in the SonicSMR project will be beneficial across sectors.

Benefits:

The proposed innovation will result in cost reduction, higher material utilisation, improved quality assurance, product customisation and reduced design cycle times in the metal AM process. The targeted application in the SonicSMR project is the manufacturing of nuclear components especially small modular reactors parts.

Brunel Innovation Centre's role

BUL is providing the high power ultrasonic system (with full assistance in the hardware/software integration into the manufacturing process), and is leading the development of AI algorithm for defects analysis and process control with parameters optimisation.

BUL has gained an extensive expertise in the areas of power ultrasonic and AI based monitoring solutions through various applications and projects. High power sonication assisted manufacturing validated to manufacturing processes involving solidifying phase, and computer vision and machine learning for in-line inspection, automated defect recognition and process monitoring AI-based analytics and decision support tool (validated for in-line inspection of Medical MEMS and manufacturing of OLEDs, OPVS and micro-electronics).

Partners:

Laser Additive Solutions Ltd LAS

Nuclear Advanced Manufacturing Research Centre (NAMRC) NAMRC

TARAZ Metrology TARAZ

IVY Technology IVY

Brunel Innovation Centre BIC

Meet the Principal Investigator(s) for the project

Professor Tat-Hean Gan - Professional Qualifications CEng. IntPE (UK), Eur Ing BEng (Hons) Electrical and Electronics Engg (Uni of Nottingham) MSc in Advanced Mechanical Engineering (University of Warwick) MBA in International Business (University of Birmingham) PhD in Engineering (University of Warwick) Languages English, Malaysian, Mandarin, Cantonese Professional Bodies Fellow of the British Institute of NDT Fellow of the Institute of Engineering and Technology Tat-Hean Gan has 10 years of experience in Non-Destructive Testing (NDT), Structural Health Monitoring (SHM) and Condition Monitoring of rotating machineries in various industries namely nuclear, renewable energy (eg Wind, Wave ad Tidal), Oil and Gas, Petrochemical, Construction and Infrastructure, Aerospace and Automotive. He is the Director of BIC, leading activities varying from Research and development to commercialisation in the areas of novel technique development, sensor applications, signal and image processing, numerical modelling and electronics hardware. His experience is also in Collaborative funding (EC FP7 and UK TSB), project management and technology commercialisation.

Related Research Group(s)

Brunel Innovation Centre - A world-class research and technology centre that sits between the knowledge base and industry.

Partnering with confidence

Organisations interested in our research can partner with us with confidence backed by an external and independent benchmark: The Knowledge Exchange Framework. Read more.

Project last modified 16/03/2021