A transportation or distribution network is a dynamic, stochastic, and complex system. Modelled as a graph, nodes fall into categories that correspond to manufacturing sources, distribution centres, and end customers. In the case of manufacturing enterprises, nodes can represent manufacturing and distribution sites that procure raw material, process them into finished goods, and distribute the finished goods to customers.

The most common objective in transportation network optimization is to find the shortest-distance distribution on a network, i.e., to determine an optimal set of routes between suppliers and customers. Today there is a growing interest in a new and much more sophisticated class of network solutions that involve multiple optimization factors like profit, service level, fault tolerance (or resilience), and environmental footprint, with the optimal solution balancing the complex trade-offs among all these parameters simultaneously.

Supply chains operate in a multi-echelon network that links supply sources, integration and manufacturing points, and end-customers, into a continuous web of commercial activity. At a company of Caterpillar’s scale, this network reaches extraordinarily high levels of complexity, making the problem clearly NP-hard.

Commercial network modelling solutions have existed since the late 1960s, and generally followed a linear solver model. This model has inherent limitations in its ability to 1) scale to problems of our size and 2) accommodate real-world variabilities in critical factors such as transit times, transportation costs, production capacities, and network architecture changes. Caterpillar’s industrial experience, and the experiments run by Caterpillar Logistics Research & Innovation, have shown that ignoring this variability leads to serious errors in the design of global networks.

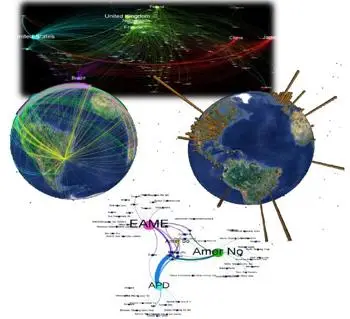

Visualization of Caterpillar's supply chain network

Visualization of Caterpillar's supply chain network

In our first round of technology development for network optimization, we down selected between multiple technologies to find those most capable of incorporating real world variabilities, tolerating missing data, and accelerating the modelling process over current commercially-available tools. These methods successfully integrated energy price volatility, ocean lane cost commitment terms, cycle stock and in-transit inventory carrying cost implications, and tariff effects. In our next phase of research, we intend to scale up these efforts on additional test problems, which requires additional innovation.

Key Achievements

- Development of conceptually new algorithms for transportation network optimization.

- Designing of highly scalable optimization tools.

- Production of consistent optimal results by using proposed algorithms.

- Integration of several dynamic real-world factors, i.e., network resilience, energy volatility models, ocean lane commitment models, etc.

- Frequent outperformance by the computed solutions over the best-known transportation network optimizations produced from commercial tools.

- Development of visualization tools to better present our findings.

See below the presentation by Tony Grichnik on the the outcome and impact of the collaborative research between Industrial AI centre.

View on YouTube

Publications

Journal Articles

- Transportation Network Optimization, Encyclopedia of Business Analytics and Optimization

A. Ogunbanwo, A. Williamson, M. Veluscek, R. Izsak, T. Kalganova, P. Broomhead. Encyclopedia of Business Analytics and Optimization (1st Edition 2014), John Wang, IGI Global. DOI: 10.4018/978-1-4666-5202-6. ISBN: 9781466652026.

- Composite Goal Methods for Transportation Network Optimization

Marco Veluscek, Tatiana Kalganova, Peter Broomhead, Anthony Grichnik. Expert System with Applications, Volume 42, Issue 8, 15 May 2015, Pages 3852–3867. DOI:10.1016/j.eswa.2014.12.017.

Conference Proceedings

- Improving Ant Colony Optimization Performance through Prediction of Best Termination Condition

M. Veluscek, T. Kalganova, P. Broomhead. Industrial Technology (ICIT), 2015 IEEE International Conference, Pages 2394,2402, 17-19 March 2015, DOI: 10.1109/ICIT.2015.7125451

ieeexplore.ieee.org

Patents

- T. Grichnik, C. Nikolopoulos, A. Byerly, E. Hill, B. Kelly, T. Kalganova, M. Veluscek, P. Broomhead (Filing Date: 15/05/2014) Supply Network Optimization Method and System for Multiple Objectives, CAT Ref.: 08350 1265 (13-1756). Provisional Patent Application.

- T. Kalganova, T. Grichnik, A. Ogunbanwo, A. Williamson, M. Veluscek, R. Izsak, P. Broomhead (Filing Date: 15/03/2014) Supply Chain Network Modeling Using an Evolutionary Strategy, CAT Ref.: 14-0155. Provisional Patent Application.

- T. Kalganova, T. Grichnik, A. Ogunbanwo, A. Williamson, M. Veluscek, R. Izsak, P. Broomhead (Filing Date: 15/10/2013) Hybrid Supply Chain Modelling, Optimisation and Presentation, CAT Ref.: 13-0770. Provisional Patent Application.

- T. Kalganova, T. Grichnik, S. Gaoetswe, and P. Parth (Filing Date: 14/09/2012) Systems and Methods for Forecasting Using Cartesian Genetic Programming, CAT Ref.: 12-1105 and 12-1106; Finnegan Ref.: 08350.1049. Provisional Patent Application.

- T. Grichnik, T. Aguilar, K. Jasti, S. Vamaraju, C. Nikolopoulos, A. Byerly, T. Kalganova, M. Veluscek, and P. Broomhead (Filing Date: 27/03/2015) Method and System for Managing Supply Chain Network with Multiple Supply Layers, CAT Ref. No.: 08350.1735-00000 (14-1941). Provisional Patent Application.

Meet the Principal Investigator(s) for the project

Dr Tatiana Kalganova - DEGREES AWARDED

PhD Napier University

Research-engineer degree Belarusian State University of Informatics and Radio-electronics, Minsk, Belarus

MSc (distinction) Belarusian State University of Informatics and Radio-electronics, Minsk, Belarus

ACADEMIC POSTS

2000-present Lecturer Brunel University London

2003-2011 Business Fellow London Technology Network, LTN Link between research activities at Brunel University London and industry

1997-2000 PhD student Napier University

1994-1997 Research Assistant Belarusian State University of Informatics and Radio-electronics

Related Research Group(s)

AI Social and Digital Innovation - Social, economic and strategic effects of AI and associated technologies. Impact of AI and related technologies on societies, organisations and individuals.

Partnering with confidence

Organisations interested in our research can partner with us with confidence backed by an external and independent benchmark: The Knowledge Exchange Framework. Read more.

Project last modified 15/07/2021