Brunel University has been approached to test this new technology in sharpening medical needles for German needle manufacturer through SARIX GMBH Swiss. The present technology uses grinding, and it is restricted to shapes available. Without optimisation of the machining parameters was achieved 10 sec time for machining and surface finish down to Ra20nm.

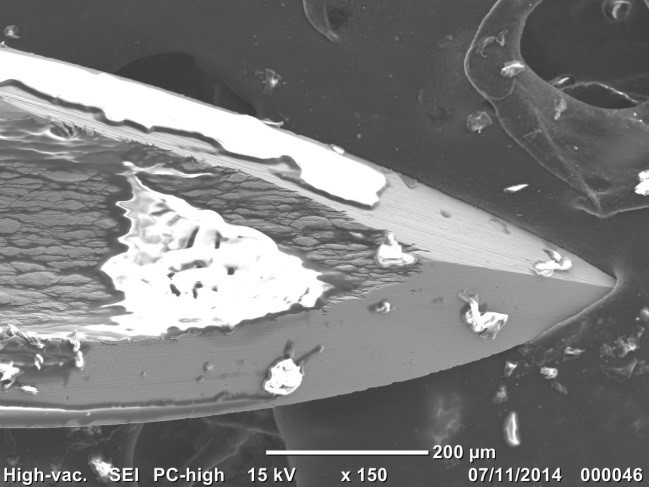

Photo 1. Typical needle manufactured using convetional grinding technology. This method bring jaged edges and burnt material at the tip of the needle

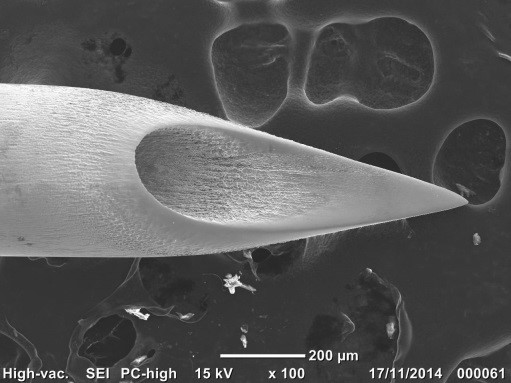

Photo 2. Micro ECM technology where the top surface can be 3D shaped depending on the needle application (bio-physical properties). The surfaces are much smoother even the internal surface.