The non-traditional manufacturing technologies include all electro-physical and electro-chemical processes and all hybrid processes and new processes developed for the needs of modern manufacturing.

Processes and technologies

These include but not limited to the following processes and technologies:

- electro-discharge machining,

- electrochemical machining,

- laser technologies,

- vibration machining of brittle materials,

- abrasive flow machining,

- electroforming,

- diamond machining,

- ultrasonic machining and many more.

Requirements

All these technologies require:

- a carrier such as a machine (mechanical equipment),

- media for the process like electrolyte, dielectric, abrasive media, special tooling (e.g. single crystal diamond),

- super-fast electronics with challenging technical parameters (Over Current protection system triggering within few nanoseconds, Pulsed power supplies giving 20V, 10A for 50 ns etc.),

- control systems

- and/or adaptive control logics depending on the process and application.

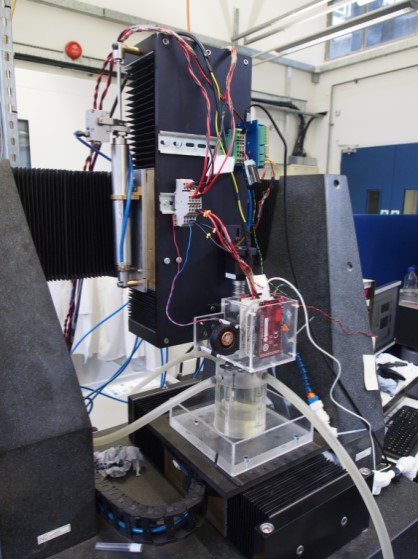

Prototypes of our µECM machines

|

Prototype One at SONPLAS GmbH for the needs of BMW |

|

Prototype Two at Brunel University London for research purposes. 3 UK companies interested in starting production of the machine. |