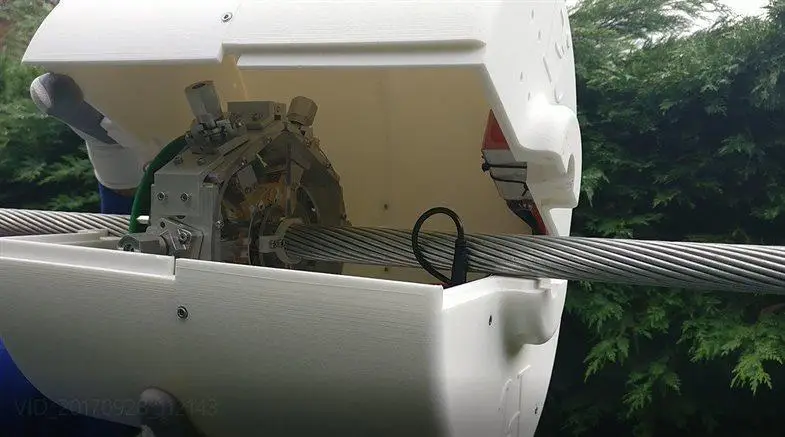

Intel-Line: Intelligent inspection system for power line cable maintenance

Background

As the electricity industry continues to expand, so do the networks of cables that provide us with power. These transmission lines are becoming longer, more complex and more detached from each other, making the whole system very difficult to maintain. Failure of power lines may expose surroundings to risk and incur high costs. Even the most modern and reliable power lines require maintenance and can be subject to wear and breakdown. Failure rates for overhead cables in the EU are around 0.17 failures per 100 circuit km/year. Although this may appear low (for example leading to 170 failures per year in France), the consequences of failure are very high (such as disruption to supply, ignition of forest fires, etc.) and so regular inspections are required with an associated high cost. Manual inspection is the most common approach. However, in order to cover hundreds of meters, ideally one needs a long-range automated system for inspection and information generation on the structural integrity of the cables.

Objectives

The goal is to further develop the intelligent inspection system for improved and efficient power line cable maintenance. Intel-Line will enable maintenance to be scheduled when required, reducing the costs associated with unnecessary maintenance and unexpected breakdowns. This will increase the availability of the power lines, reducing downtime, which will lead to increased efficiency in the power industry by means of predictive maintenance, and also offer an improved and more efficient management for power lines and grids.

Benefits

Intel-Line will provide the following benefits to the power transmission industry:

- Enable the industry to perform just-in-time maintenance, as a result of knowing actual defect sizes and criticality.

- Reduce operating and maintenance costs by as much €150milion/yr.

- Improve safety by reducing or eliminating helicopter line inspection and attached harness inspection.

- Improve the quality of visual inspection practices commonly used today.

- Support the power companies in their goal of maintaining a sustainable electricity supply industry to household consumers.

- Decrease the costs associated with catastrophic maintenance failures.

Project Partners

- Nesne

- Montage Cablage Installation

- Plant Integrity Ltd

- Brunel University London

For more information, please visit the Intel-Line website.

Meet the Principal Investigator(s) for the project

Related Research Group(s)

Brunel Innovation Centre - A world-class research and technology centre that sits between the knowledge base and industry.

Partnering with confidence

Organisations interested in our research can partner with us with confidence backed by an external and independent benchmark: The Knowledge Exchange Framework. Read more.

Project last modified 12/03/2021