Mooring systems are critical for the success of all offshore floating renewable energy devices, which are constantly pushed to their extreme limits in their high energy environments. Importantly the use of moorings enhances depolyability, enabling deeper waters, closer to shore to be utilised with a lower cost. In the past 10 years there has been significant research focused on ropes resulting in the production of lighter and stronger products. As consequence weaknesses in the systems now occur in the rope in-line and end connectors with critical areas causing chaffing of the rope, resulting in its premature failure. The objective of this study is to design a new multi-material hybrid connector that will be lighter, easier to assemble and enhance the lifespan of the mooring system. The innovation arises from the use of the next generation of nylon/Al composite materials which when combined, exhibit higher strength, high corrosion resistance, low coefficient of friction, and are lightweight. For offshore renewables energy devices, this will result in increased deployability, increased reliability and longer in-service times. This will yield an increase in energy output and improvement in safety.

The STORM connector is a multi-partner effort that offers a novel solution for this mooring challenge: The novel design in full compression offers the opportunity for the use of lighter materials hence offering a more deployable solution and easier maintenance. The novel multi-material solution proposed not only offers a weight reduction but due to the anti-corrosion, anti-fouling and UV-resistant properties of both the core and the outer shell the life-span of the connector increases of 30%.

The Basaltium core, an innovative composite produced by Brunel University is a composite made of a recycled aluminium matrix reinforced with basalt fibres offering a sustainable and environmentally friendly solution, furthermore, the Nylacast proprietary low-friction nylon solution Oilon dramatically decreases the wear of the rope.

STORM project partners:

Outcomes

The STORM project was a feasibility study with the final scope to produce 5 connectors to be tested at 30 tonnes.

We successfully produced the prototypes and tested them in a laboratory environment at 40 tonnes also including fatigue testing. The connectors designed for a 40 tonnes break-load weigh 13 kg, while its counterpart in stainless steel would have weighed 37 kg. The connector withstood the testing successfully proving the validity of the concept.

On the 25th of January, the STORM connector was awarded the category Rushlight award 2018 for responsible product and on the 26th of January the connector was showcased to the industry during a mooring masterclass workshop organised by EMEC at Brunel University

The team will now focus on raising funds to upscale the connector to 100 tonnes breaking loads that can be used for wave and also small scale offshore wind floating devices. We then aim to further upscale the connector to up to 800 to 1000 tonnes within the next 5 years in order to satisfy also full scale floating wind end users.

STORM connector being successfully tested at TTI’s facility in Wallingford, Oxfordshire

STORM connector being successfully tested at TTI’s facility in Wallingford, Oxfordshire

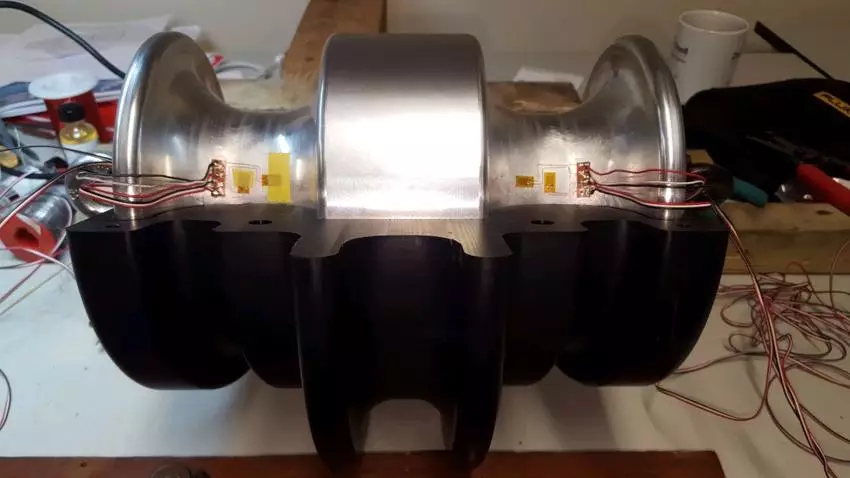

Section of connector showing aluminium core fitted with strain gauges ready for testing. The black outer sheath is made from specialist low-friction nylon

Section of connector showing aluminium core fitted with strain gauges ready for testing. The black outer sheath is made from specialist low-friction nylon

STORM consortium members receiving the Rushlight 2018 category award for responsible product or service

STORM consortium members receiving the Rushlight 2018 category award for responsible product or service

Meet the Principal Investigator(s) for the project

Dr Brian McKay - Dr Brian McKay is currently a senior lecturer in BCAST at Brunel University. Prior to this he was a university assistant at the Institute of Casting Research (ICR), University of Leoben, Austria (2003-2009) and a research fellow at UMIST (2003). He obtained his DPhil from Oxford University, MSc from The Queen’s University of Belfast and BEng from the University of Ulster.

He has over 20 years’ experience in solidification research with 1 Patent on novel metal composites (UK Patent No. 1714401.5), 1 trademarked product (Basaltium), and over 30 papers and two co-edited monographs published in the field. His main expertise lies in the fields of castings, composites, interfaces, coatings, and their characterisation using advanced electron microscopy techniques. Whilst his research interests in the past have been centred on understanding heterogeneous nucleation during solidification, these interests now also include Metal Matrix Composites/Nano-composites, Powder Metallurgy and Electroplating. Over the past 9 years Brian has been involved in 11 successful grant awards totalling ~£30M. He is currently PI on a new €11M Horizon 2020 project LightMe, was the Co-ordinator and PI of a €1.6M EU-FP7 grant, HardAlt, involving 12 partners from 6 countries that focused on finding an alternative nano-composite coating for Hard Chrome, a CoI on the £4.5M EPSRC - LiME grant that investigated solidification mechanisms, PI on the £150k “Characterization and Processing of High Thermal Conducting Al-MMCs” grant sponsored by the Korean Institute of Technology (KITECH) that examined the potential of CNT MMCs for High Power Light emitting Diodes (HPLeD’s), PI on the £300k STORM Innovate UK/EPSRC in which a new composite Al core was produced for offshore marine energy mooring connectors and Co-I on the £10M EPSRC Manufacturing Hub grant. He is a Fellow of the Higher Education Academy and Institute of Cast Metal Engineers and has sat on the Technical/Educational Board of the latter as an adviser since 2012. In addition he is a member of the EPSRC Peer Review College and an Associate Editor of the International Journal of Cast Metal Engineers. Over the years Brian has collaborated with many companies including, LSM, BMW, Alcoa and Alcan. He has given several invited presentations throughout Europe and in 2006 he received a TMS Magnesium Application Award for his work in nucleation and more recently has been a recipient of the Rushlight Responsible Product or Service Award 2017-18 for the STORM connector.

Related Research Group(s)

Experimental Techniques Centre - A highly regarded cross-disciplinary characterisation facility, with specialist staff that have expertise from various scientific disciplines, e.g. biology, metallurgy, geology and engineering.

Wolfson Centre for Sustainable Materials Development and Processing - Research into the development and processing of new materials including nano-materials, nano-phosphors and nanostructured carbon, biofuels, polymers and bio-polymers.

Partnering with confidence

Organisations interested in our research can partner with us with confidence backed by an external and independent benchmark: The Knowledge Exchange Framework. Read more.

Project last modified 21/11/2023