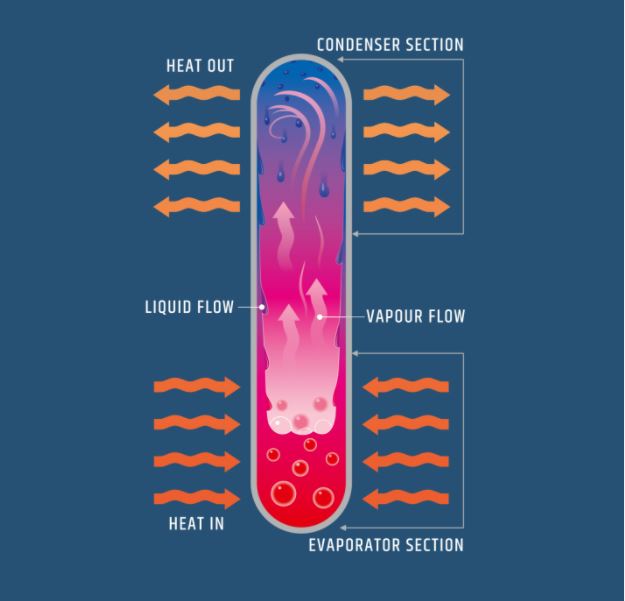

A heat pipe transfers thermal energy passively from a hot to a cold stream by a boiling condensation cycle inside a hermetically sealed metal tube. In this way, heat from the hot area can be transferred very efficiently to a cold part of the pipe. The diagram shows the principle of the heat pipe: The sealed pipe contains a working fluid. Absorbing heat at the lower end, the liquid vaporises and carries the thermal energy upwards to the condenser section, where it encounters a lower temperature. As a consequence, the vapour condensates (back to a liquid) and thereby releases heat. The liquid runs down the inner walls back to the evaporator section where the process starts over again.