Background

In the UK the exploitable offshore wind resource is at 6200TWhpa, ~18 times present UK electricity consumption and hence could provide all of the UK's electricity requirement with minimal emission and visual impacts. The major barrier to further exploitation is that the levelized cost of electricity (LCOE) from offshore wind is £140/MWH. 2-3 times higher than other key renewable sources: onshore wind, solar and. The high LCOE is caused by the severe environment which results in high operational, reliability and maintenance (O&M) costs.

Seabed turbine foundations (largely monopile structures) O&M accounts for at least than 25% of all life cycle O&M costs, mostly caused by marine biofouling amounts to 10% of the LCOE and are incurred through the use of divers, ROVs, a support vessel and substantial human team. Even with the deployment of state of the art fouling prevention technology, the fouling thickness deposited on foundations grows continuously, eventually causing stress induced corrosion and crack defects.

Objectives

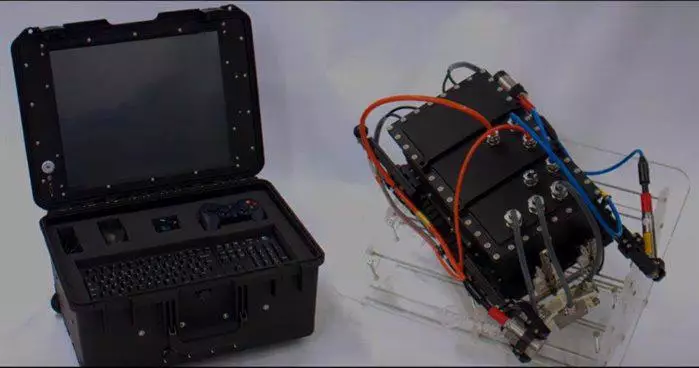

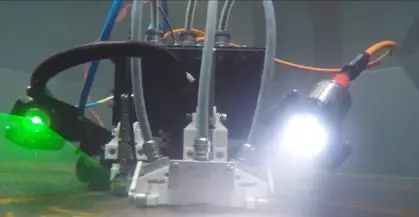

The project vision is to replace this expensive and hazardous technology with an intelligent fouling monitoring and cleaning management system (RobFMS) implemented by an autonomous working team of at two or more small mobile robots operating with AI enabled cost minimisation.

Benefits

The system would save more than £15kpa/MW (50%) of existing monopile fouling management costs, which is a significant contribution to realising the full environmental advantages of offshore wind. It is also adaptable to other types of offshore turbine foundation.

Project Partners

- InnotecUK

- Brunel University London

Meet the Principal Investigator(s) for the project

Professor Tat-Hean Gan - Professional Qualifications CEng. IntPE (UK), Eur Ing BEng (Hons) Electrical and Electronics Engg (Uni of Nottingham) MSc in Advanced Mechanical Engineering (University of Warwick) MBA in International Business (University of Birmingham) PhD in Engineering (University of Warwick) Languages English, Malaysian, Mandarin, Cantonese Professional Bodies Fellow of the British Institute of NDT Fellow of the Institute of Engineering and Technology Tat-Hean Gan has 10 years of experience in Non-Destructive Testing (NDT), Structural Health Monitoring (SHM) and Condition Monitoring of rotating machineries in various industries namely nuclear, renewable energy (eg Wind, Wave ad Tidal), Oil and Gas, Petrochemical, Construction and Infrastructure, Aerospace and Automotive. He is the Director of BIC, leading activities varying from Research and development to commercialisation in the areas of novel technique development, sensor applications, signal and image processing, numerical modelling and electronics hardware. His experience is also in Collaborative funding (EC FP7 and UK TSB), project management and technology commercialisation.

Related Research Group(s)

Brunel Innovation Centre - A world-class research and technology centre that sits between the knowledge base and industry.

Partnering with confidence

Organisations interested in our research can partner with us with confidence backed by an external and independent benchmark: The Knowledge Exchange Framework. Read more.

Project last modified 12/10/2023