Batt2TheFuture: Second life batteries for future applications

Background

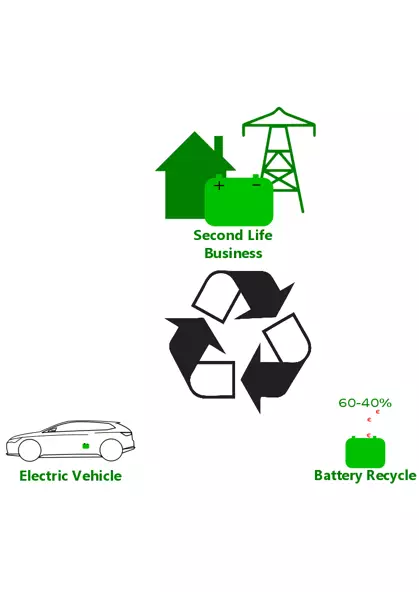

The decarbonisation of the transport sector in the UK will see the migration from solely internal combustion powered vehicles to electric or hybrid vehicles only, as early as 2030. This will result in the exponential growth of spent Electric Vehicle (EV) batteries stockpiled, as they must be replaced every 7-10 years. After this period, the EV batteries may still hold as much as 80% of their capacity, which often can be used in other applications. In Batt2TheFuture, a fast automated process will be developed to enable fast sorting of battery cells to rebuild high quality and consistent second-generation battery packs.

Batt2TheFuture is an automated process that uses disruptive ultrasound technology and AI algorithms to inspect and grade spent battery cells. The process inspects each cell from a battery pack/module and then grades them according to their respective State of Health (SoH) and State of Charge (SoC). The technology combination enables in-depth inspection, increased speed of cell assessment and processing capacity scalability - these have been missing in current spent battery inspection solutions on the market.

Objective

Based on the results of the assessment, the cells are sorted and refurbished in preparation for their second-life. The repurposed battery packs are then deployed to applications whose power requirements align with their SoH and SoC values. Currently, the evaluation of SoH and SoC takes hours which is not practical for processing large quantities of cells. Moreover, the process of dismantling and testing cells is not competitive in UK as it is a labour-intensive task. The automation of this process will allow reducing the cost and increasing the UK competitiveness in the 2nd life battery industry. This will also have an environmental impact thereby drastically reducing battery waste and an economic one thanks to reducing the lifetime cost of the battery.

Therefore, Batt2TheFuture will facilitate the utilisation of the full value of spent EV batteries as well as contributing towards ensuring that the decarbonisation of the transport sector will not just be a transfer of carbon emissions from the vehicles themselves to battery raw material extraction.

Benefits

This project will provide new capabilities in ultrasonic based inspection and grading of cells that will set the first step towards the development of the high throughput and economically viable second-life battery facilities in the UK that can out-perform global competitors.

Batt2TheFuture offers:

- Increased throughput - Batt2TheFuture will work at a rate previously unavailable to the market (1-second/cell).

- Increased recovery - manufacturers will recover all viable cells including those condemned when module level inspection is used.

- Increased product quality -- The quality of each cell used for second-life battery can be guaranteed thereby boosting the reputation manufacturer in the market.

- Pre-emptive regulatory compliance --EV battery recycling is clearly going to put the onus on manufacturers, hence Batt2TheFuture will allow local manufacturers to get ahead as well as setting the industrial standard in the UK

Brunel Innovation Centre's Role

Brunel Innovation Centre will provide the ultrasonic technology that will be used to inspect the EV battery cells' SoC and SoH. They will also provide the AI algorithms that will be used for in-line inspection quality control in addition to cell assessment and classification.

The main objectives are:

- Selection of transducer/receiver for data acquisition on SOH and battery failure.

- Optimisation of the operation parameters of the ultrasonic transducers to acquire reliable and repeatable data.

- Topology and transducer mounting design to optimise the system performance.

- Combination of signal processing and machine learning for reliable and near instantaneous determination of the SoH tailored to different battery cell designs and capacities.

Project Partners

- INNVOTEK LTD

- ACELERON LIMITED

- MEV LIMITED

- BRUNEL UNIVERSITY LONDON

Meet the Principal Investigator(s) for the project

Related Research Group(s)

Brunel Innovation Centre - A world-class research and technology centre that sits between the knowledge base and industry.

Partnering with confidence

Organisations interested in our research can partner with us with confidence backed by an external and independent benchmark: The Knowledge Exchange Framework. Read more.

Project last modified 09/01/2024