Lighter alternative materials are necessary for automobiles to meet the requirements for future Euro 7 and similar regulations. As a result of the increased demand for ever more lightweight components, many industries are trying to exploit the use of composite materials. While the costs of composites have dropped dramatically over the past decade, effective joining of these materials to conventional metal parts in the automotive sector remains a significant challenge. Existing joining/assembly solutions present a number of limitations, with major manufacturers inclined to use mechanical fasteners. However, these types of fixings raise multiple issues, including the risk of fibre and matrix damage and slow assembly times. Alternative measures include adhesives, which tend to be epoxy-based, require extended curing times and the use of toxic chemicals. The consortium's innovation BRACE (led by Gestamp) is a rapid assembly method that requires no fixings or adhesives and can be easily recycled when end-of-life is reached. It is based on advanced polymer coating material (PCM) joining technology. The exploitation of the BRACE joining system will drive growth right across the supply chain.

Objective

This project seeks to overcome a number of high-risk technical challenges in order to adapt the PCM process and make it suitable for thermoplastic composite to metal joining. Hence, the objectives that will be investigated in this project are:

- Develop dissimilar material joining system

- Technology feasibility study

- Model and optimise dissimilar joining system

- Design and develop case study parts

- Develop joining system lap-prototype

- Testing, evaluation and validation

- Dissemination and exploitation

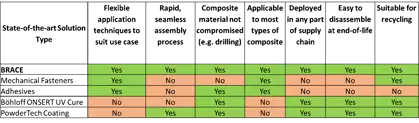

Comparison of BRACE and Other SOA against key system requirements.

Comparison of BRACE and Other SOA against key system requirements.

PCM joining process and end-of-use

PCM joining process and end-of-use

Project Logo

Project Logo

Benefits

The successful completion of the BRACE project can offer the following benefits:

- Light weighting

- CO2 reduction

- Fuel economy improvement

- Improved process efficiencies

- Design for disassembly that allows effective end of life recycling

- Exploitation for future niche electric vehicles

Brunel Composite Centre's Role

BCC’S role in this project is to develop a high-fidelity finite element model of the dissimilar joining system. This includes reviewing the state-of-the-art methods used to model similar joining systems; then create and set up the system in a CAE software. Finally, BCC will inform partners with the optimum parameters that can be used to produce the required joint performance based on the simulation results.

Project Partners

Meet the Principal Investigator(s) for the project

Dr Mihalis Kazilas - Dr Mihalis Kazilas is the Director of the Brunel Composites Centre. He has more than 20 years of experience in the composites processing area. He received his PhD in Advanced Materials from Cranfield University back in 2003. His main field of expertise are polymers characterisation and polymer composites manufacturing and joining processes. He is author of several refereed scientific publications in the area of advanced composites manufacturing and process optimisation. Mihalis is a creative thinker who enjoys problem solving and able to work with different stakeholders to achieve the optimum results in both technical and managerial environments.

Work experience:

Sep 2019 – present: Business Group Manager, Polymer and Composite Technologies, TWI, UK

June 2019 – present: Director of the Non-Metallics Innovation Centre, a joint initiative between TWI, Saudi Aramco and ADNOC

Oct 2016 – present: Centre Director, Brunel Composites Innovation Centre, Brunel University London, UK

Feb 2012 – 2019: Section Manager, Adhesives, Composites and Sealants (ACS) section within the Joining Process Group at TWI, UK

May 2006 – Jan 2012: R&D Consultant, Project Engineer, Collaborative Projects Operations Manager at INASCO, Greece

Related Research Group(s)

Brunel Composites Centre - Shared research and technology capabilities, specialising in novel composites processing and joining technologies applied to industrial environments.

Partnering with confidence

Organisations interested in our research can partner with us with confidence backed by an external and independent benchmark: The Knowledge Exchange Framework. Read more.

Project last modified 21/11/2023